Cylinder Inspection and Testing

There are two inspections that can be carried out on cylinders, a visual inspection and a hydrostatic test depending on which is required for that cylinder. The cylinder valve will be serviced along with the test.

Cylinders will be stamped and a certificate of testing issued. For oxygen clean cylinders this cleaning is offered as an extra. Any work required to bring a cylinder into test like internal shot blasting to remove rust, repainting or valve replacement can be offered prior to work being carried out.

Turn around time depends on how busy we are but usually within the week. All cylinders are leak tested and filled prior to collection by the customer.

Service & Repairs

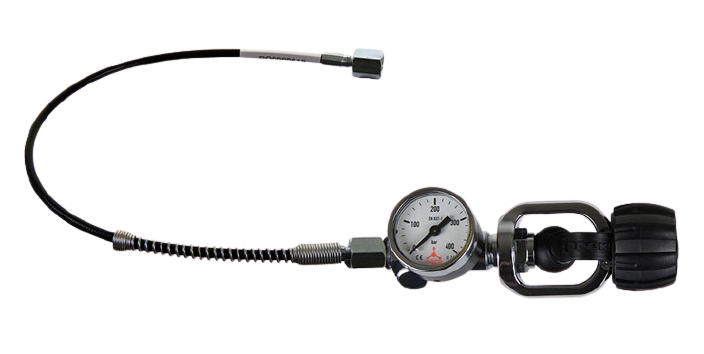

The majority of makes of regulator can be serviced and again done on site. Full strip down, clean and test is carried out. Only original manufacturers service pack parts are used. Cost is based on labour plus parts used.

We also service BCD’s, dive computer battery replacement, and many other diving related items.

Please ask if you would like something servicing.

We are able to offer repairs on most drysuits but some will need to go back to the manufacturer. Typical repairs/replacement include:

- Neck Seal

- Wrist Seal

- Zips

- Boots

- Pressure Test for leaks

Rebreather Servicing

Types of rebreather that can be serviced are:

- AP Diving Classic, Inspiration, Evolution and 2020

- Poseidon MK 6 & 7

- Hollis Prism 2

Full service and replacement of parts as per manufacturers guidelines. Rebreather head sent to manufacturer for service.

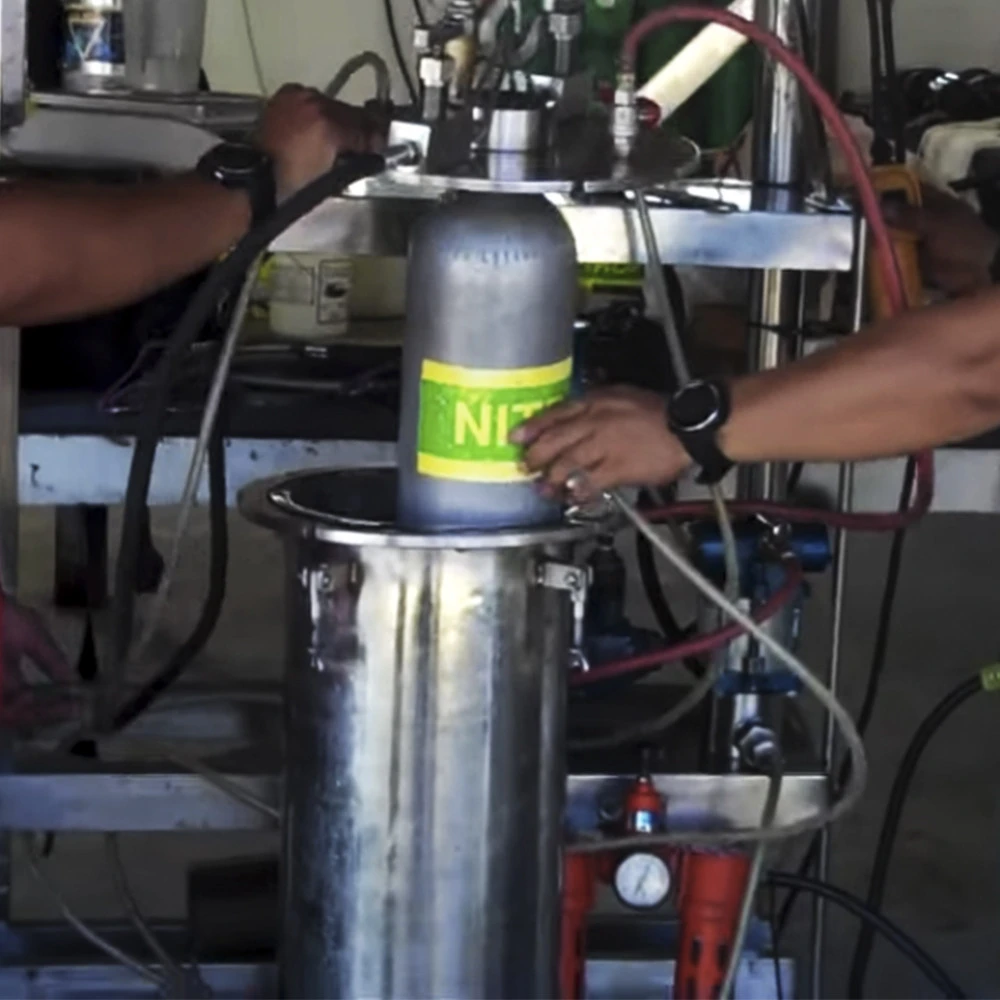

Diving and Cylinders

Diving, Airgun and Paintball

Diving

Rebreathers, Medical & Aviation

Rebreathers and Open Circuit Diving

Airgun & Paintball

Fills to 230 & 300 Bar for airgun cylinders

Cylinder testing done on site with up to 5 year test certificates issued

A selection of new and preowned cylinders available to purchase

Spare parts, gauges,whips and adaption hoses